What is an Ag/AgCl electrochemical sensor

An electrochemical sensor is a sensor that can figure out the status by using redox potential. It is used for the following cases;

- for environmental and water quality analyses, measurement of the amount of copper, arsenic, and mercury and the like contained in the water.

- for measurement of the blood glucose level, lactic acid, urine sugar sensor, and glutamic acid etc as a transducer part of a biosensor etc...

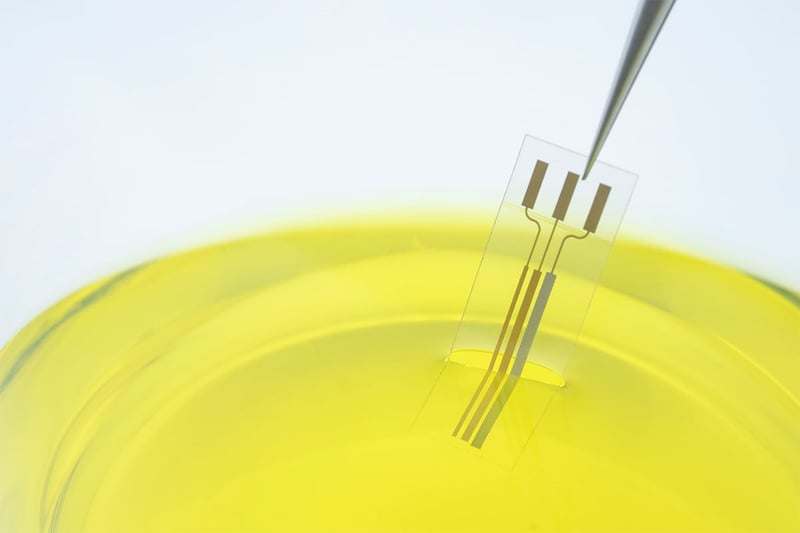

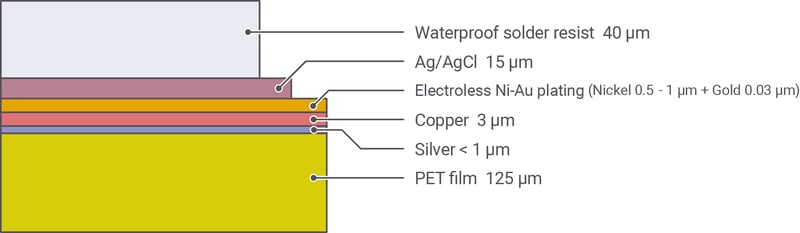

Example of Layer constitution

Benefits of making electrochemical sensors with P-Flex®PET

Usually, the electrochemical sensor is manufactured only by silk screen printing. However, when it is combined with the 3 μm copper wiring of P-Flex® PET;

- Reduction of wiring resistance value.

- Cost benefit compared to gold paste printing by making gold electrode with gold flash.

- Because it is a PET base that doesn't absorb water, it can reduce water absorption induced sensor sensitivity trouble, can also be used for flow cell and such.

- Can be produced in small batches.

- Production price is negotiable.

For the prototypes, we plan to provide a one-stop service with paste spreading instead of part mounting for roughly the same price.

Sensors to measure thickness of target molecule based on Oxidation-Reduction Potential(ORP).

A sensor has two gold electrodes and one Ag-AgCl electrodes.

Applications

Gas sensors, pH sensors, biosensors, water quality sensors, ORP sensors

Industries

Measurement equipment, IoT sensor devices

Related article