- IMPC®(In-Mold Printed Circuit)Solution

- Example: overhead console (prototype)

- How the overhead console works (video)

- Applications

- P-Flex® Flex PCB Prototype Specifications

- Development Example

・IMPC® Right Angle Connector Sample

・IMPC® touch sensor with integrated connector

・Multi-Functional IMPC® Sample

・IMPC® Microwell Plate with Electrochemical Sensor - Related article

- Inquiry Form

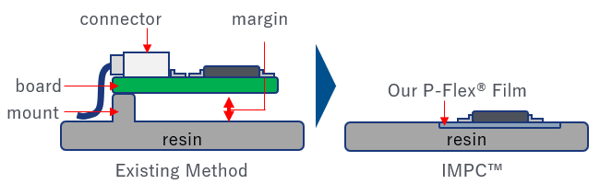

IMPC®(In-Mold Printed Circuits) is a design and manufacturing solution that provides an integrated, optimized design for the entire component instead of the traditional manufacturing method where plastics and electronic circuits are designed and manufactured separately.

By integrating the resin and the circuit, a wider range of optimized designs can be achieved, resulting in various advantages such as weight reduction, thinness, and cost reduction.

Using proprietary inkjet technology and proprietary high-speed electroless copper plating, P-Flex® circuit film, which is produced completely mold-less, is molded in three dimensions and then integrated with resin through injection molding (film insert molding).

Our manufacturing process achieves low resistance and soldering, prevents ion migration, and lowers material costs. This process overcame various problems found in the past with other printing and three-dimensional wiring methods.

In addition, the initial capital investment can be reduced because existing injection molding machines for film insert molding are used for the process of film 3D molding and resin integration.

The above manufacturing process is just one example, and the process may vary slightly depending on the design of the product.

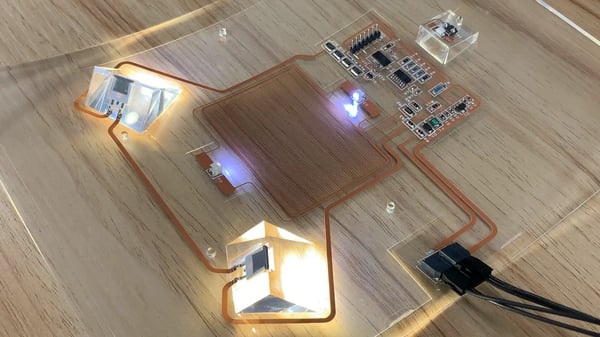

Example: overhead console (prototype)

This is an image sample of an IMPC® that we have made as a prototype (our asset). As a result of applying IMPC® to an overhead console, which is designed to resemble buttons and lights on the ceiling of an automobile, we were able to obtain various advantages.

- Thinness : The assembly gap and substrate holding structure can be reduced, and the thickness is less than 5 mm(excluding the light guide part)

- Lighter weight : Three times lighter than commercially available parts with similar functions

- Cost reduction : Reducing the number of parts and wiring connectors drastically reduced the cost of mass production by several dollars (*Our own calculation).

How the overhead console works (video)

Touch sensor, a microcontroller, high power LEDs (with a current value of a few amps), a physical switch and other components are soldered together. You can check out the features in the video below.

- Add a variety of features while maximizing interior space

- Thinner and lighter touch sensor LED lighting

- Placing antennas and sensors on the surface

- Install Heaters in the center console and armrests for efficient temperature control

Industries

- Automotive, consumer electronics, industrial equipment

Positioning of this manufacturing specification

These manufacturing specifications are the basic specifications for P-Flex® production, and details can be agreed upon through individual consultation. For particular specifications, please get in touch with us.

| Substrate | Transparent heat-resistant PET film: 50 µm, 125 µm |

| Line width / Spacing(L/S) | 200 / 200 μm |

| Hole diameter | 0.5 mm min. |

| Outline-pattern spacing |

0.3 mm min. |

| Standard Copper trace thickness | 3µm (please consult us if you require a thickness of more than 3 µm) |

| Panel size | 223 x 393 mm max. |

| Wiring layer | Single-sided |

| Soldermask coating | UV inkjet printing (transparent) |

| Legend printing | UV inkjet printing (white) |

| Surface finish | Oxidation prevention treatment, Electroless nickel gold plating(option) |

| Outline cutting | Laser cut |

| Hole drilling | Laser cut |

| Stiffeners | Film stiffeners can be used to adapt to connectors of 200 µm or 300 µm in total thickness. Component mounted parts can be adapted by using FR-4 stiffeners of 0.1, 0.3, 0.5, 1.0, and 1.6mm in thickness. |

| Inspection | Visual inspection + opens/shorts test |