Japanese / English

- Toward a Sustainable Society

- Elephantech’s Environmental Communication

- Metal Inkjet Printing Technology Drastically Reduces Environmental Impact Without Affecting Product Performance

- Climate Change: Effects on Reducing CO2 Emissions

- Detailed Comparison of Subtractive Manufacturing Methods and Pure Additive™ Processing for Double-sided PCBs(Reduction in Water Consumption and Toxic Substance Emissions)

- Contributing to the Sustainable Development Goals (SDGs)

- Related Article

- Inquiry Form

With the increasing momentum to reduce greenhouse gas emissions, there is a growing trend towards greater environmental consciousness.

In January 2022, the California State Senate passed a bill requiring all companies with annual gross revenues of $1 billion or more to report their emissions annually for all scopes, including direct emissions (Scope 1), emissions from the purchase and use of electricity (Scope 2), and indirect emissions, including emissions from the company's supply chain (Scope 3). 1

Following the revision of Japan’s Corporate Governance Code in 2021, companies listed on the Tokyo Stock Exchange’s top market – to be newly established as the Prime Market in Spring 2022 – will be required to disclose information following the recommendations of the Task Force on Climate-related Financial Disclosure (TCFD). 2

Amid such global trends, Elephantech believes it is a corporate responsibility to communicate on efforts made in reducing environmental impact and has worked on the visualization of its sustainability efforts from the three angles of “Natural resources,” “Carbon footprint,” and “Water consumption.”

On a mission to “Making the world sustainable with new manufacturing technologies,” Elephantech will strive to make the electronics industry sustainable.

1: California Senate Passes Bill for First Law in US Requiring Companies to Disclose all GHG Emissions

2: IFRS Foundation announces International Sustainability Standards Board, consolidation with CDSB and VRF, and publication of prototype disclosure requirements

Copper Consumption

Carbon Footprint / Water Consumption

Manufacturing Costs

- A fundamental process of modern manufacturing that has been used for over 100 years

- A major issue is that the stacking and scraping processes generate large amounts of liquid wastes, resulting in significant environmental impact

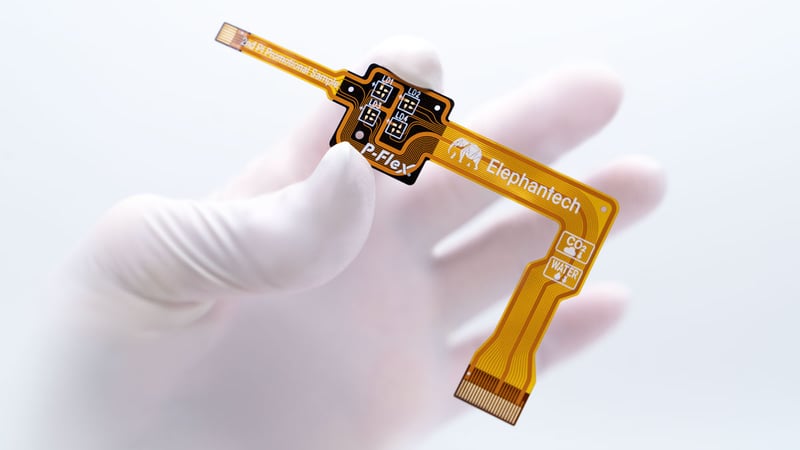

- The method transforms nanosized metal into ink, forming a metal pattern and printing directly and as required

- The printing process in itself has an extremely low environmental impact in terms of waste, water consumption and CO2 emissions

- Inkjet printing of metals is an overwhelmingly complex technology, but Elephantech was the first - and currently only1 - company to succeed in bringing it to market and mass production

Our P-Flex® PI Sample

- We used LCA(Life Cycle Assessment) to compare the carbon footprint of conventional PCB manufacturing methods to that of Elephantech’s Pure Additive™ processing1. This comparison has been analyzed and calculated by us and evaluated by a third-party organization.

- The figures for conventional manufacturing methods were taken from Carbon Footprint Analysis of Printed Circuit Board2, a study conducted by The Hong Kong Polytechnic University.

The paper mentioned above is a detailed LCA evaluation using actual data from Shenzhen Sunshine Circuits Technology Co., Ltd, and Elephantech also followed its evaluation procedure.

|

Item |

Existing |

ELT method |

Estimation logic |

Simulation logic |

|

Materials - CCL |

15.9 |

0.2 |

25μm polyimide film |

Proportional to the number of layers |

|

Materials - DES |

9.1 |

0.0 |

No DES process |

No change |

|

Materials - Electroless |

0.3 |

1.2 |

From existing, assuming |

Proportional to the number of layers and copper thickness |

|

Materials - Gold Plating |

7.5 |

7.5 |

Same as existing |

No change |

|

Materials - Other |

6.6 |

2.4 |

Removes materials needed for |

No change |

|

Materials - Waste process |

9.4 |

0.5 |

1/20 of existing, given the waste |

Proportional to the number of layers and copper thickness |

|

Production energy |

37.1 |

10.9 |

Simulation of actual data |

Proportional to the total material carbon footprint |

|

Transportation&Packaging - |

17.0 |

1.8 |

From existing, assuming |

Proportional to the total material carbon footprint |

|

Waste management |

0.8 |

0.0 |

1/20 of existing, given the waste |

Proportional to the number of layers and copper thickness |

|

Total |

103.8 |

24.5 |

1: Assumptions: Copper film thickness 6.6um

| Major item | Process | Waste liquid |

| Start material | CCL(Film+Cu) | Omit the waste liquid in CCL production |

| Drilling process | Via hole drilling | |

| Washing | Waste water | |

| Catalyst addition | Cleaner | Alkali waste liquid |

| Washing | Alkali waste liquid(weak) | |

| Soft Etching | Heavy-metal acid waste liquid (contains Cu) | |

| Washing | Acid waste liquid(weak) | |

| Predip | Acid waste liquid | |

|

Add palladium catalyst |

Acid waste liquid, Recovery | |

| Washing | Acid waste liquid(weak) | |

| Electroless Cu | Accelerator | Sn, Acid waste liquid (Pd contain) |

| Washing | Acid waste liquid(weak) | |

| Electroless Cu | Heavy-metal acid waste liquid (contains Cu) | |

| Washing | Alkali waste liquid(weak) | |

| Drying | ||

|

Electrolytic Cu |

Cleaner | Acid waste liquid |

| Washing | Acid waste liquid(weak) | |

| Predip | Acid waste liquid | |

|

Electrolytic Cu |

※None since it is circulated | |

| Washing | Acid waste liquid(Cu contain) | |

| Rust prevention | Alkali waste liquid(weak) | |

| Washing | Alkali waste liquid(weak) | |

| Drying | ||

| DF |

Soft Etching |

Acid waste liquid(Cu contain) |

| Washing | Acid waste liquid(weak) | |

| Drying | ||

|

DF laminate |

||

| Exposure | Exposure | |

| DES | Developing | DFR, Alkali waste liquid |

| Washing | Alkali waste liquid(weak) | |

| Etching | Acid waste liquid, Recovery | |

| Washing | Acid waste liquid(weak) | |

|

Stripping |

DFR, Alkali waste liquid | |

| Washing | Alkali waste liquid(weak) | |

| Drying |

| Major item | Process | Waste liquid |

| Start material | Film | |

| Drilling process | Via hole drilling | |

| Printing | Printing | |

| Drying | ||

| Sintering | ||

| Cleaner | Alkali waste liquid | |

| Circulated Washing | ※None since it is circulated | |

| Electroless Cu | Electroless Cu | Heavy-metal acid waste liquid (contains Cu) |

| Washing | Alkali waste liquid(weak) | |

| Rust prevention | Waste water | |

| Circulate Washing | ※None since it is circulated | |

| Drying |