This image is for illustrative purposes only.

AMC(Additive Manufacturing Center)

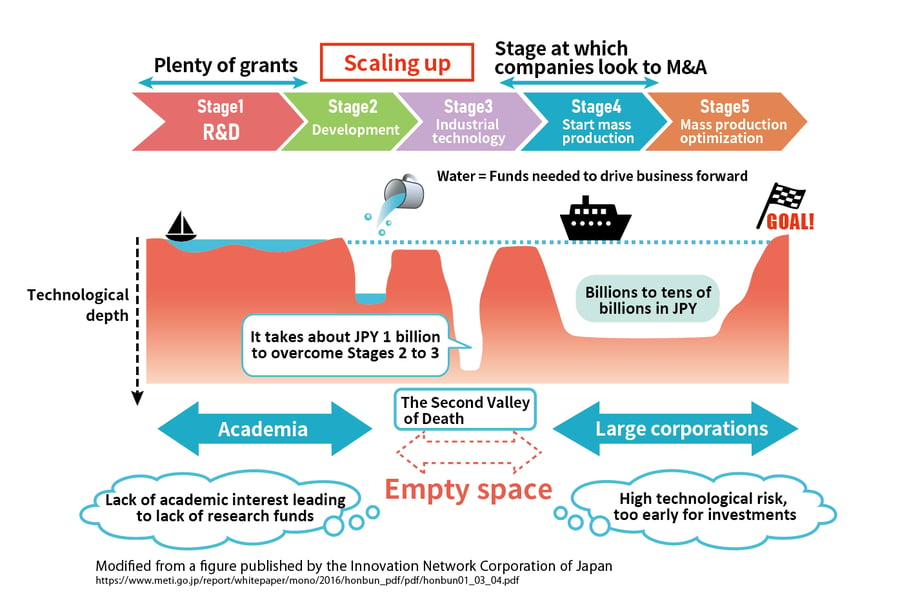

AMC is a co-creation organization that closely works with customers through trial and error, from casual experimentation to mass production. AMC hopes to bring AM(*) inkjet manufacturing to more fields through this endeavor.

*AM (additive manufacturing) is a manufacturing method that uses inkjet and other techniques to selectively layer materials on the targeted area. Achieving waste-free manufacturing through digital technologies is essential in Industry 4.0 as well as Society 5.0, and is thought to contribute to the SDGs.

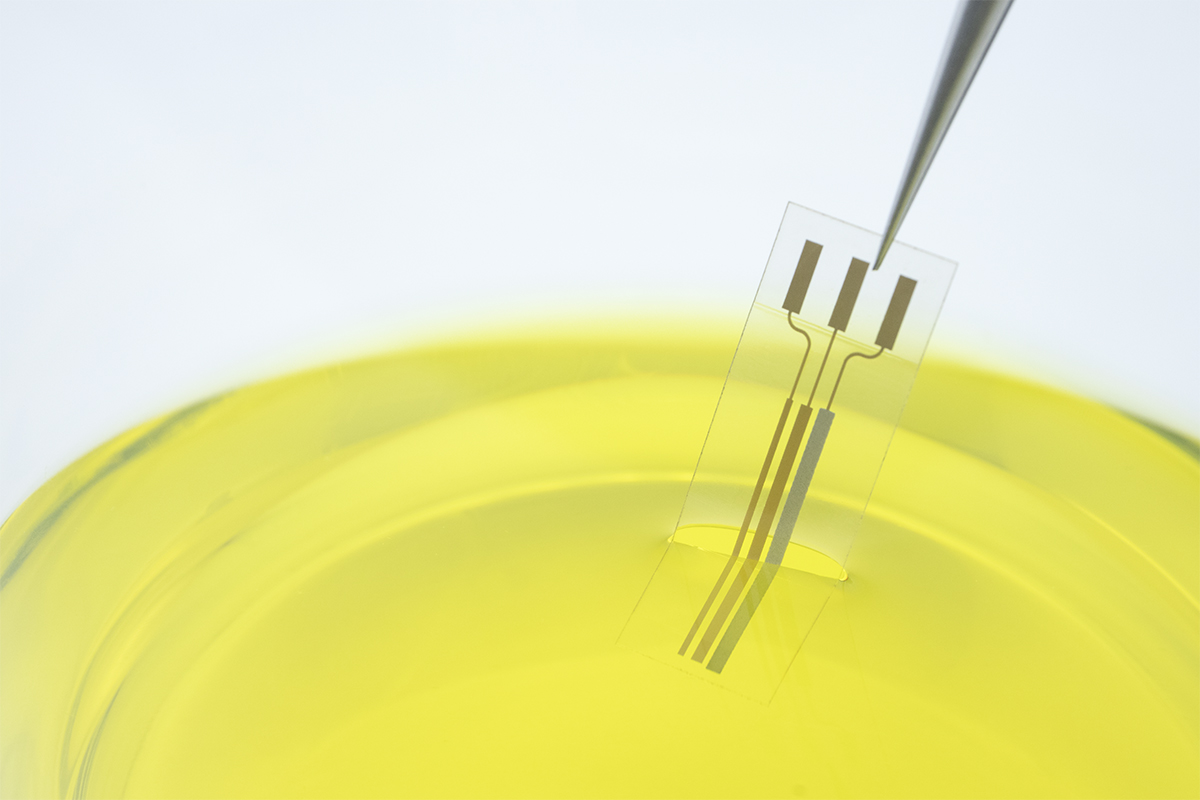

- Ink Discharge Evaluation

We will verify whether the ink is discharged correctly from the inkjet printhead. - Print Evaluation

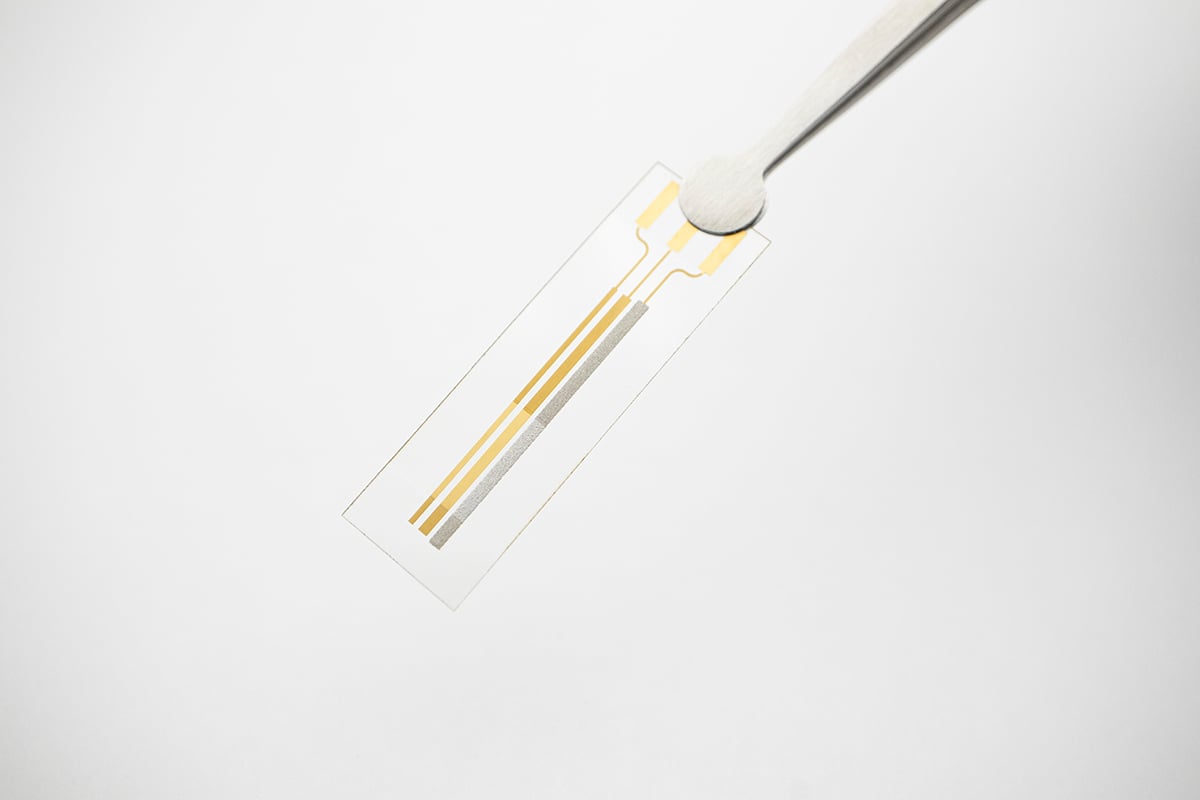

We will verify whether circuits and patterns are printed correctly onto the substrate by the inkjet printing device. - Prototyping

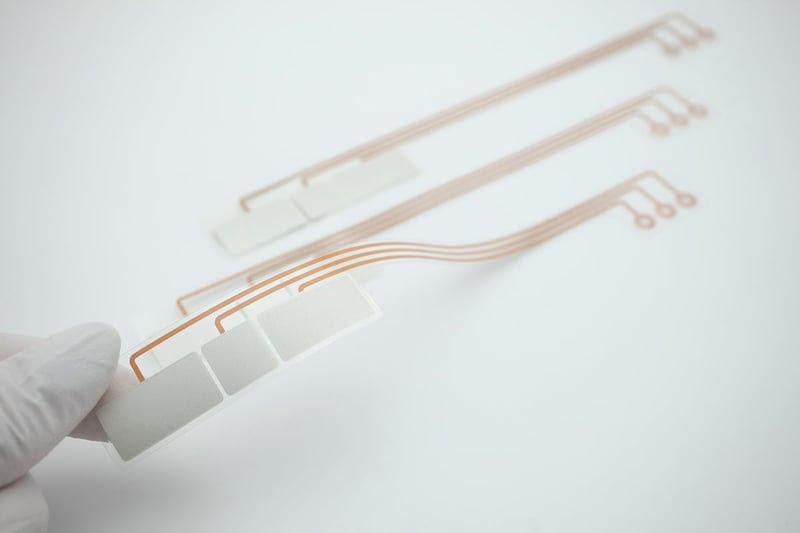

We will make prototypes using an inkjet printer or other means according to your request. - Contract Manufacturing

Based on the prototyping results, the manufacturing of the product may be outsourced to us starting from small lots.