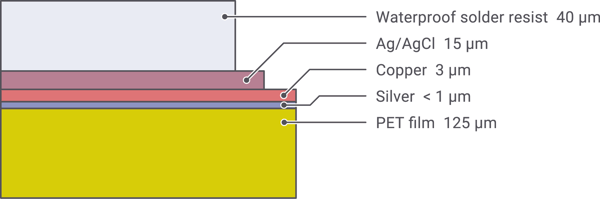

Ag/AgCl biological electrode made with P-Flex® boasts an overwhelmingly low resistance to electrodes due to its copper wiring and has an advantage in that parts mounting is possible. In addition, our inkjet technology has more advantages in the following;

- Can be manufactured at a reasonable price in a short period of time because the mold is only for Ag/AgCl paste applying.

- Can be produced in medium and small batches.

- You may choose between PET film or polyimide film substrates.

- Available for material ratio adjustment of Ag/AgCl paste and prototyping for iontophoresis.

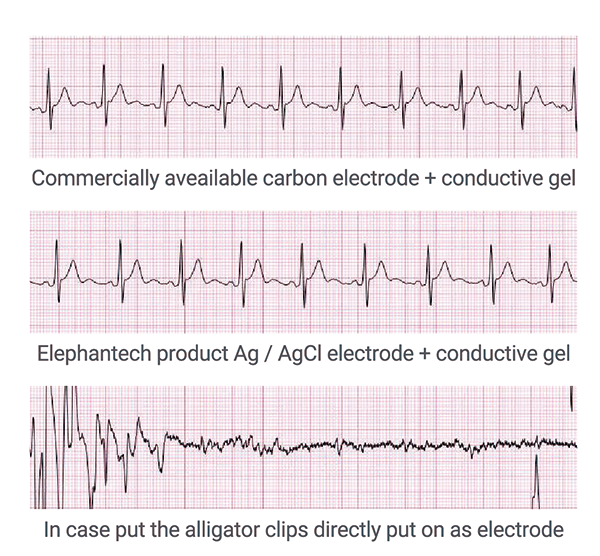

The biological electrode detects the electric the bioelectric potential such as ECG(electrocardiogram), EEG(electroencephalogram) or EMG(electromyogram).

In addition, "Generally, nickel silver or silver electrodes are used for electrode derivation of ECG or EEG though, it is recommended for monitoring to use Ag/AgCl electrodes used stably over a long time, and having low polarizing potential between the skin and the electrodes."1.

*1 Yoji Ishiyama, The Performance required for the sensor for biomedical signal measurements, The Japanese journal of medical instrumentation, Vol.80,No.1(2010), p.21.

biomedical electrodes using silver/silver chloride electrodes

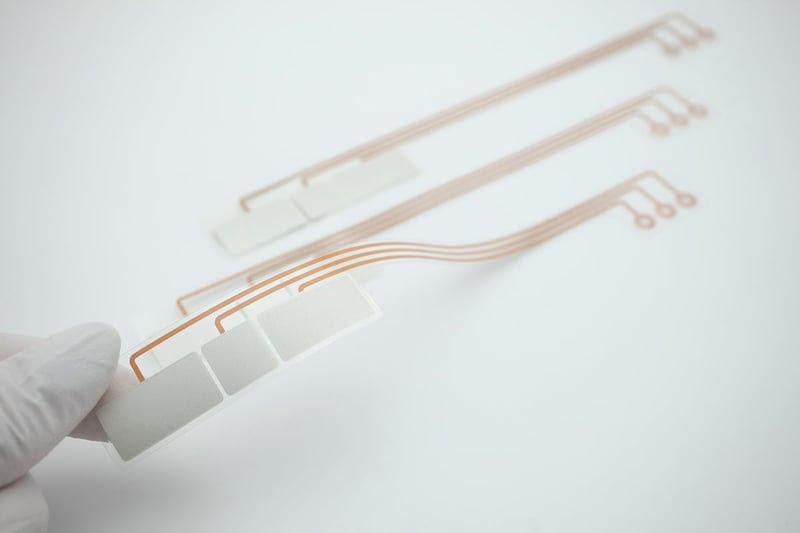

What we have prepared here is a set of sensors connected to our P-Flex® biomedical electrodes.

Biomedical electrodes are used to measure EMG, ECG, and EEG.

Here are ones we have coated with silver/silver chloride.

This is currently connected here, forming a + (plus), - (minus), and N electrode combination.

Let's go ahead and take an EMG measurement.

If you take a look at the screen, you can see that it is in a relaxed state with no movements. When you move, you can see that there is a repetition of contraction and relaxation.

This is how our P-Flex® biomedical electrodes can be used to take EMG measurements.

Applications

ECG(electrocardiogram), EEG(electroencephalogram), EMG(electromyogram)

Industries

Medical devices, human-computer interfaces, robots

For general and technical inquiries, please contact us from the form below;