Japanese / English

Quality testing [PI]

- Specimen

- Results of insulation resistance of surface layer

- Peel Strength of Conductor test

- Results of resistance to flexural fatigue test

- Resistance to bending test

- Migration test

- Chemical resistance test

- Results of Dry heat test

- Results of Cold test

- Results of Thermal Shock (Low Temperature and High Temperature)

- Results of Thermal Shock (Immersion, Hot Bath)

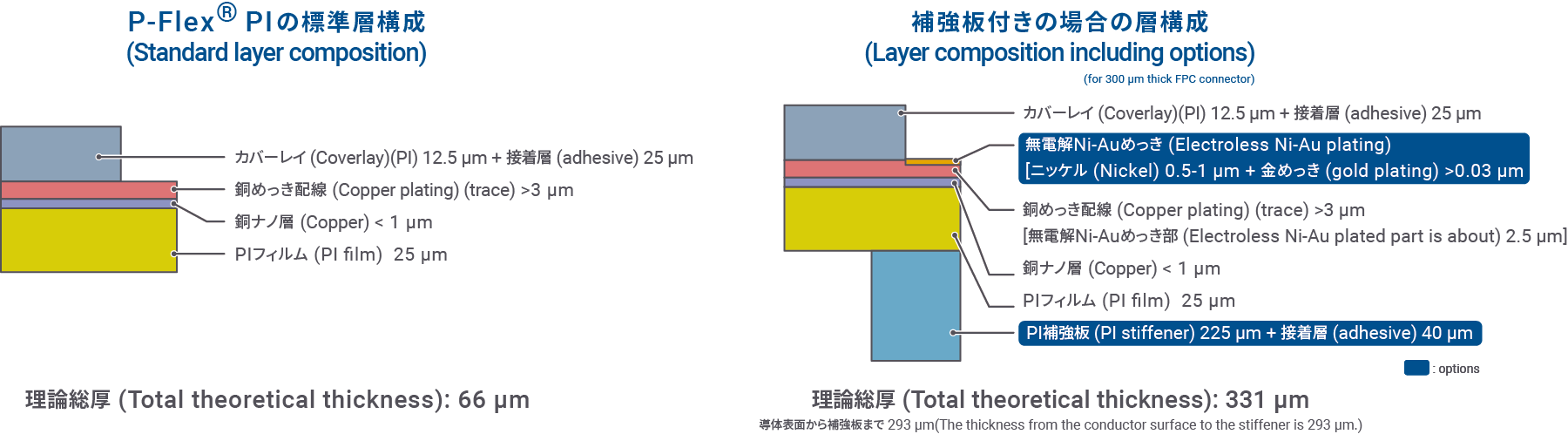

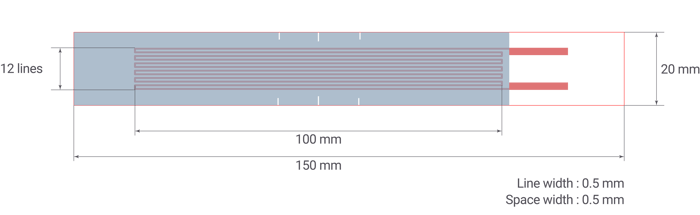

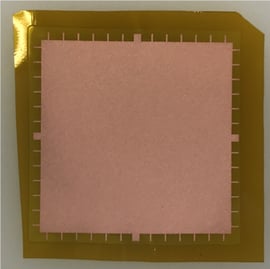

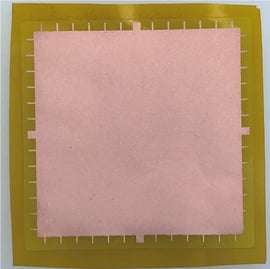

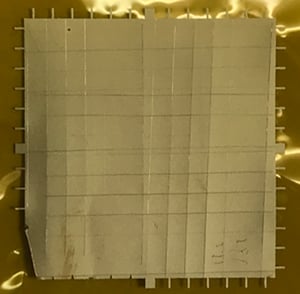

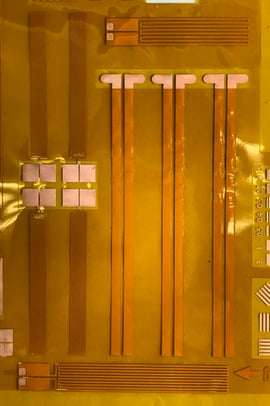

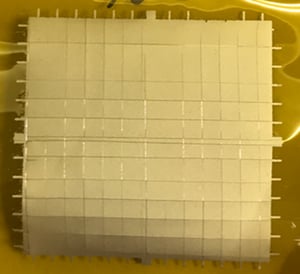

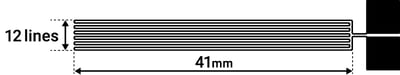

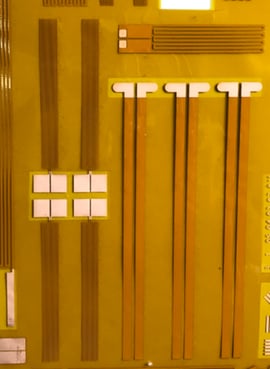

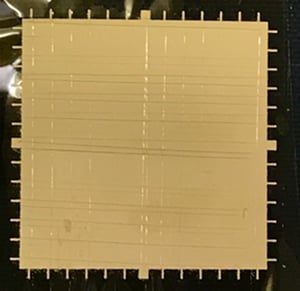

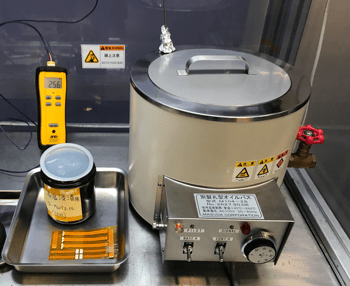

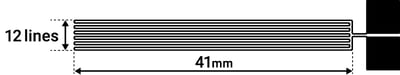

0. Specimen

Each test was evaluated using the following specimen.

1. Results of insulation resistance of surface layer

1.Applicable standard

Applicable standardJIS C 5016 7.5

2.Test condition

Overview of insulation resistance measurement

Applied voltage : 500V(DC)

Applied voltage : 500V(DC) Applied time : 60 sec

Gap width : 1.0 mm

3.Test results

In this test, a voltage of 500V (DC) was applied to Elephantech's P-Flex® PI test specimens for 60 seconds.

After the test, no mechanical damage, flashover (surface discharge), sparkover (airborne discharge), breakdown (dielectric breakdown), or other abnormalities were observed in the test specimens.

After the test, no mechanical damage, flashover (surface discharge), sparkover (airborne discharge), breakdown (dielectric breakdown), or other abnormalities were observed in the test specimens.

| Sample No. | Resistance[MΩ] |

| #1 | >2099 |

| #2 | >2099 |

| #3 | >2099 |

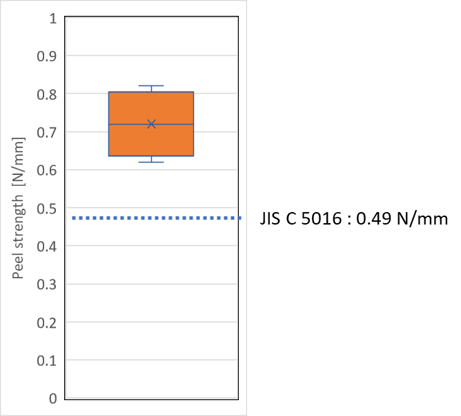

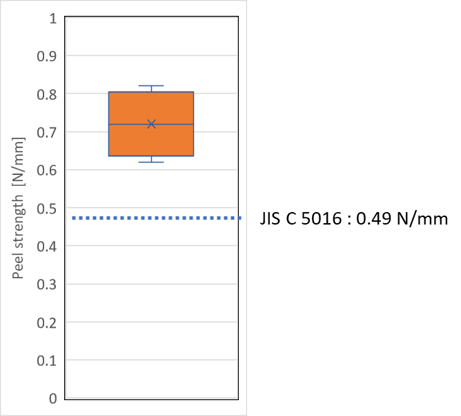

2. Peel Strength of Conductor test

Tested according to the conditions specified in JIS C5016 8.1. Sufficient peel strength was confirmed.

1.Applicable standard

JIS C 5016 8.1

2.Test condition

The conductor is peeled 90° to the surface from which the conductor is removed. The peeling speed is approximately 50 mm/minute.

3.Test results

Peel Strength: 0.63-0.84(n=4)

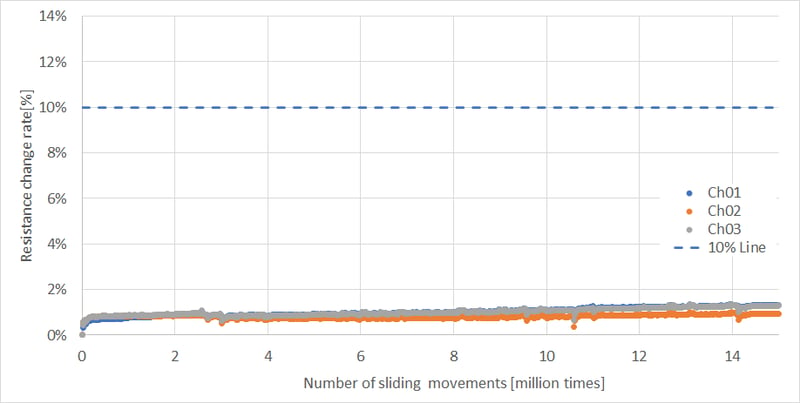

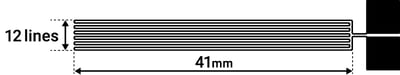

3. Results of resistance to flexural fatigue test

1.Applicable standard

JIS C 5016 8.6

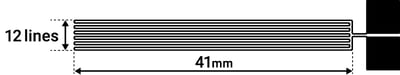

2.Test condition

Flexing rate:5Hz(300rpm)

Flexing radius (r):5mm

Sliding distance (l):22mm

Wiring pattern Line/Space=0.5mm/0.5mm

Flexing radius (r):5mm

Sliding distance (l):22mm

Wiring pattern Line/Space=0.5mm/0.5mm

3.Test results

Resistance to flexural fatigue test was conducted in accordance with JIS C5016 8.6. , and data up to 16 million cycles was obtained(n=3).

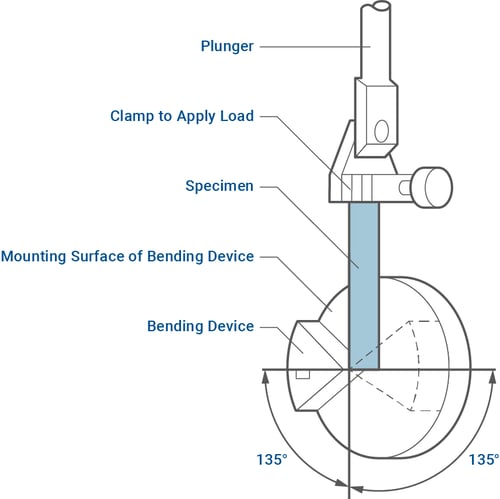

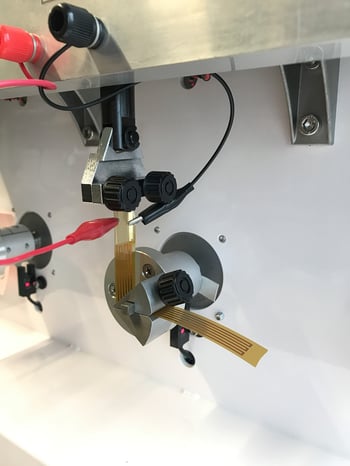

4. Resistance to bending test

1.Applicable standard

JIS C 5016 8.7

2.Test procedure

(1) Bending conditions

・Rate : 175rpm

・Angle : ±135°

・Load : 4.9N

・Bending radius : 0.38mm

(2) Continuous measurement of conductor resistance (disconnection determined when resistance exceeds 100Ω)

(3) Number of samples : 10p

・Rate : 175rpm

・Angle : ±135°

・Load : 4.9N

・Bending radius : 0.38mm

(2) Continuous measurement of conductor resistance (disconnection determined when resistance exceeds 100Ω)

(3) Number of samples : 10p

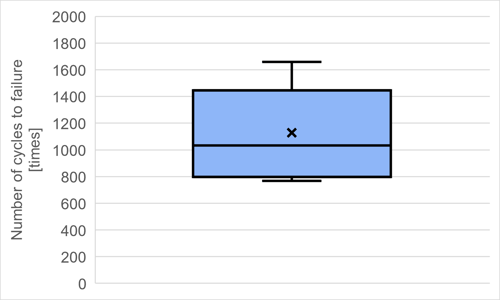

3.Test results

Number of cycles to failure: 767~1,659times(n=10)

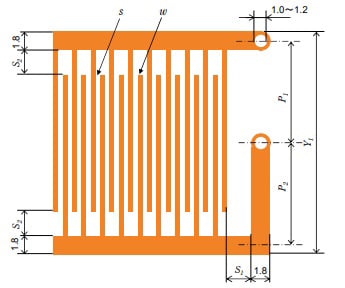

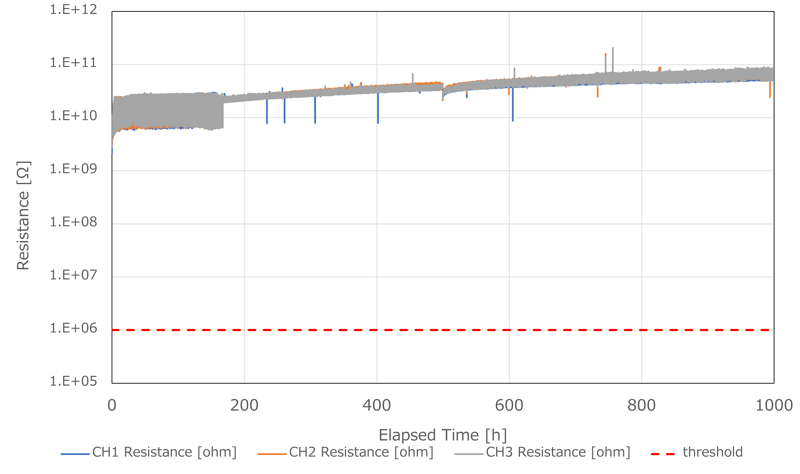

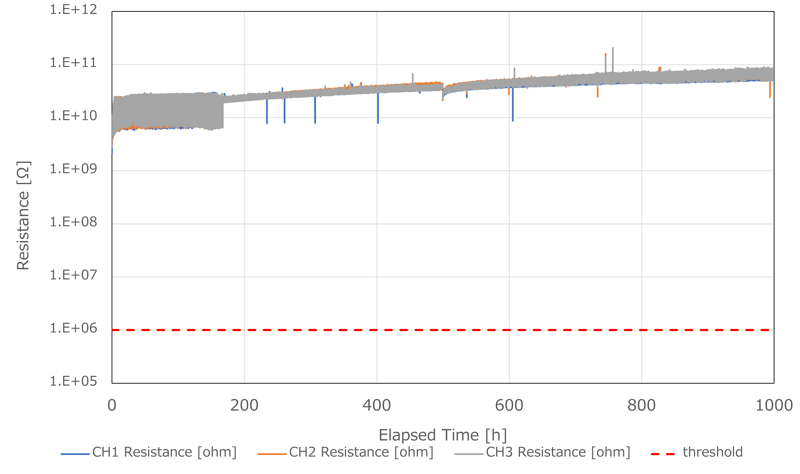

5. Migration test

1.Applicable standard

JPCA-ET04

2.Test condition

(1) Environmental conditions: 85°C, 85%RH

a) Applied voltage: 100 VDC.

b) Testing time : 1000H

c)Number of samples : 3p

(2) Sample shape : JPCA 6.4.5-4 compliant

w/s=0.20mm/0.20mm

S1=S2=1.35mm

P1=5.0mm P2=3.8mm

Y1=10.6mm

a) Applied voltage: 100 VDC.

b) Testing time : 1000H

c)Number of samples : 3p

(2) Sample shape : JPCA 6.4.5-4 compliant

w/s=0.20mm/0.20mm

S1=S2=1.35mm

P1=5.0mm P2=3.8mm

Y1=10.6mm

3.Test results

No migration occurs. (n=3)

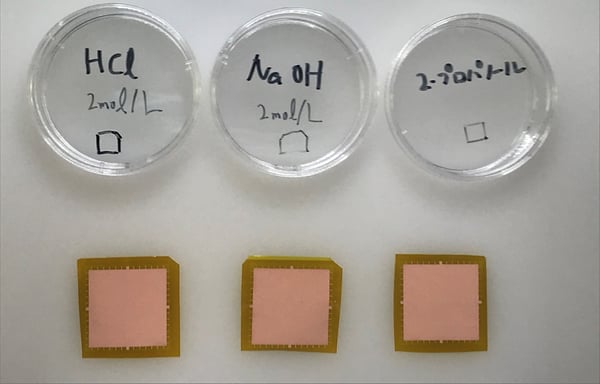

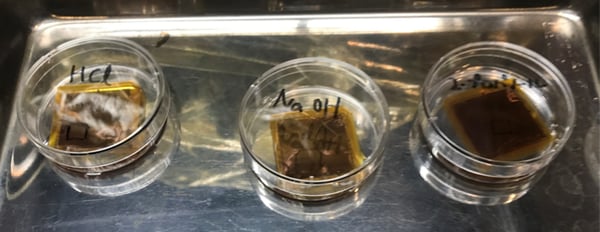

6. Chemical resistance test

1.Applicable standard

JIS C 5016

"Test Methods for Flexible Printed Wiring Boards" 10.5 "Resistance to Chemicals"

"Test Methods for Flexible Printed Wiring Boards" 10.5 "Resistance to Chemicals"

2.Test condition

In this chemical resistance test, the test specimens were immersed in 2 mol/L hydrochloric acid solution, 2 mol/L sodium hydroxide solution, and 2-propanol as alcohol for 5 minutes ± 30 seconds, and then their appearance was checked. The test specimens did not show any abnormalities in appearance after immersion in acid, alkali and alcohol for 5 minutes.

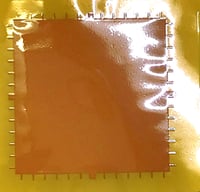

3.Initial condition

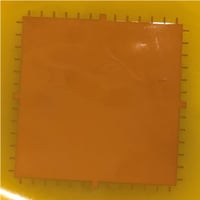

4.Testing condition

5.Test results

No floating, swollen, wrinkled, cracked, broken plating or peeling pad on conductor.

| Acid (Hydrochloric acid) |

Alkali (Aqueous solution of sodium hydroxide) |

Alcohol (2-propanol) |

|

|---|---|---|---|

| Before |  |

|

|

| After |  |

|

|

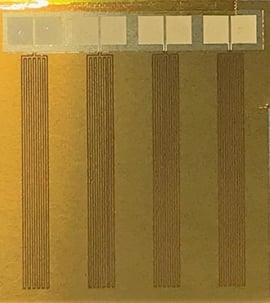

7. Results of Dry heat test

1.Applicable standard

JIS C 60068-2-2

2.Test condition

150℃/1000H

2 Type specimens (resistance and insulation resistance)

2 Type specimens (resistance and insulation resistance)

3.Test results

・No remarkable rate of change in resistance.

・No floating, swollen, wrinkled, cracked, broken plating or peeling pad on conductor.

・No floating, swollen, wrinkled, cracked, broken plating or peeling pad on conductor.

・Rate of change in resistance

Wiring pattern: w/s = 0.2mm / 0.2mm

| Before the test [Ω] | After the test[Ω] | Rate of change in resistance |

|---|---|---|

| 3.37 | 3.41 | 1.25% |

| 3.41 | 3.46 | 1.31% |

| 3.06 | 3.09 | 1.10% |

| 3.03 | 3.07 | 1.27% |

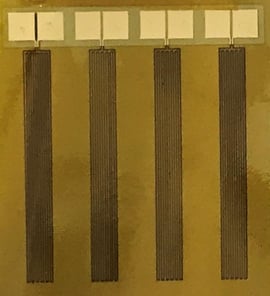

・Insulation resistance

Wiring pattern space = 1.0mm

| Before the test[MΩ] | After the test[MΩ] |

|---|---|

| >2099 | >2099 |

| >2099 | >2099 |

| >2099 | >2099 |

・Appearance

| Before the test | After the test |

|---|---|

|

|

・Tape peeling test result

No peeling

No peeling

8. Results of Cold test

1.Applicable standard

JIS C 60068-2-1

2.Test condition

150℃/1000H

2 Type specimens (resistance and insulation resistance)

2 Type specimens (resistance and insulation resistance)

3.Test result

・No remarkable rate of change in resistance.

・No floating, swollen, wrinkled, cracked, broken plating or peeling pad on conductor.

・No floating, swollen, wrinkled, cracked, broken plating or peeling pad on conductor.

・Rate of change in resistance

Wiring pattern: w/s = 0.2mm / 0.2mm

| Before the test[Ω] | After the test[Ω] | Rate of change in resistance |

|---|---|---|

| 3.76 | 3.74 | -0.47% |

| 3.45 | 3.45 | -0.07% |

| 4.01 | 4.00 | -0.25% |

| 3.74 | 3.74 | -0.07% |

・Insulation resistance

Wiring pattern space = 1.0mm

| Before the test[MΩ] | After the test[MΩ] |

|---|---|

| >2099 | >2099 |

| >2099 | >2099 |

| >2099 | >2099 |

・Appearance

| Before the test | After the test |

|---|---|

|

|

・Tape peeling test result

No peeling

No peeling

9. Results of Thermal Shock (Low Temperature and High Temperature)

1.Applicable standard

JIS C 5016 9.2

2.Test condition

Ta=-65℃(30min) ⇔ 125℃ (30min) × 100 cycle

2 Type specimens (resistance and insulation resistance)

2 Type specimens (resistance and insulation resistance)

3.Test result

・No remarkable rate of change in resistance.

・No floating, swollen, wrinkled, cracked, broken plating or peeling pad on conductor.

・No floating, swollen, wrinkled, cracked, broken plating or peeling pad on conductor.

・Rate of change in resistance

Wiring pattern: w/s = 0.2mm / 0.2mm

| Before the test[Ω] | After the test[Ω] | Rate of change in resistance |

|---|---|---|

| 3.29 | 3.29 | 0.11% |

| 2.99 | 2.99 | -0.08% |

| 1.84 | 1.85 | 0.28% |

| 1.71 | 1.70 | 0.59% |

・Insulation resistance

Wiring pattern space = 1.0mm

| Before the test[MΩ] | After the test[MΩ] |

|---|---|

| >2099 | >2099 |

| >2099 | >2099 |

| >2099 | >2099 |

・Appearance

| Before the test | After the test |

|---|---|

|

|

・Tape peeling test result

No peeling

No peeling

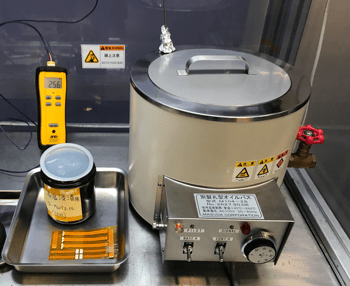

10. Results of Thermal Shock (Immersion, Hot Bath)

1.Applicable standard

JIS C 5016 9.3

2.Test condition

Subject the specimen to the thermal shock of the cycles of the following table.

| Step | Temperature ℃ | Duration min | Immersing liquid | |

| Cycle | 1 | 260 +5 -0 | Three to five | Silicone oil |

| 2 | 20 ± 15 | Within 15 | (Transfer) | |

| 3 | 20 | 2-propanol | ||

| 4 | Within 15 | (Transfer) | ||

Appearance of Oil bath

3.Test result

・No remarkable rate of change in resistance.

・No floating, swollen, wrinkled, cracked, broken plating or peeling pad on conductor.

・No floating, swollen, wrinkled, cracked, broken plating or peeling pad on conductor.

・Rate of change in resistance

Wiring pattern: w/s = 0.2mm / 0.2mm

| Before the test[Ω] | After the test[Ω] | Rate of change in resistance |

|---|---|---|

| 3.25 | 3.45 | 6.2% |

| 3.22 | 3.42 | 6.2% |

| 3.21 | 3.44 | 7.2% |

| 3.15 | 3.45 | 9.5% |

・Insulation resistance

Wiring pattern space = 1.0mm

| Before the test[MΩ] | After the test[MΩ] |

|---|---|

| >2099 | >2099 |

| >2099 | >2099 |

| >2099 | >2099 |

・Appearance

| Before the test | After the test | ||

|---|---|---|---|

|

|

|

|