Japanese / English

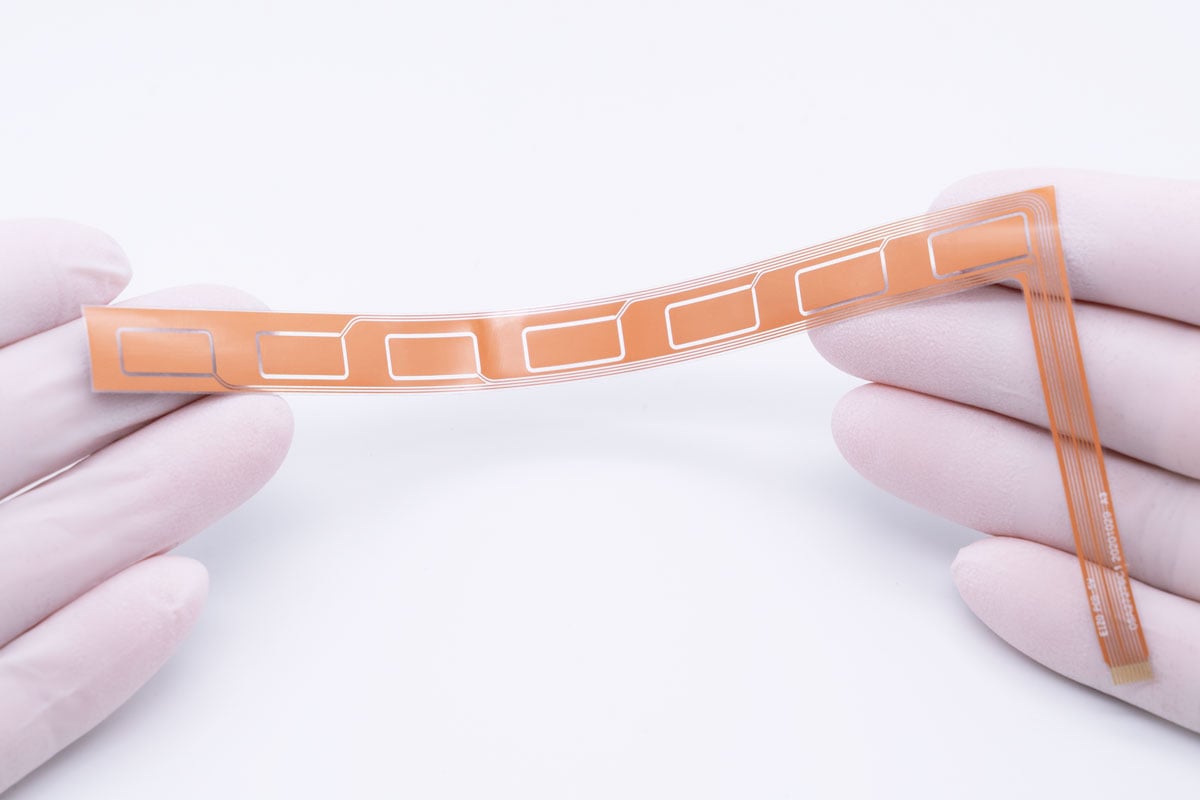

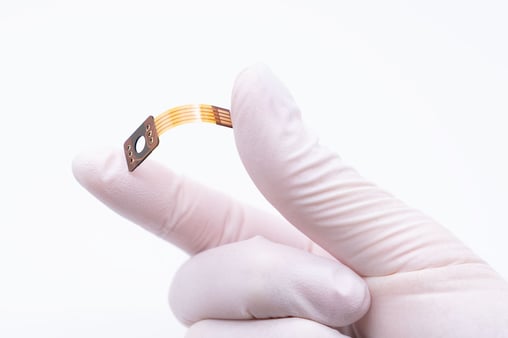

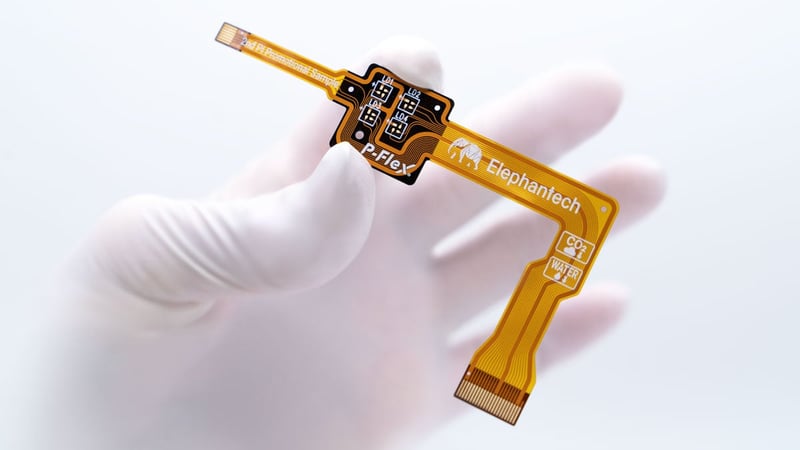

P-Flex🄬 Standard sample

About Elephantech's manufacturing method (Pure Additive™️ method)

P-Flex® – Print Metal Ink Directly and then Apply Copper Plating

The Pure Additive™️ method involves converting metal into nanoparticle ink state, which is then printed on a substrate using an inkjet printer. The metal is then grown by electroless copper plating to form a circuit. This technology requires fewer manufacturing processes compared to conventional methods, resulting in significant reductions in environmental impact and improved cost performance.

(* Patent No. 6300213)

The world's first practical application using printing technology

Taking the example of printed circuit boards, the conventional manufacturing method was an extremely long process in which copper foil is manufactured, laminated with film (production of CCL), and laminated with photosensitive materials before the desired copper pattern is achieved by dissolving and discarding the copper foil from unnecessary parts by exposure, development, and etching.

Our process achieves the desired copper pattern by printing the metal onto film and growing it, not only forgoing the need for copper foil manufacturing and CCL manufacturing processes but also eliminating the need for the etching process to dissolve and discard the copper foil.

Our process achieves the desired copper pattern by printing the metal onto film and growing it, not only forgoing the need for copper foil manufacturing and CCL manufacturing processes but also eliminating the need for the etching process to dissolve and discard the copper foil.

Elephantech's P-Flex Printed Circuit Board Manufacturing Process (2:15)

Environmentally Friendly, Proprietary Technologies

Amid such global trends, Elephantech believes it is a corporate responsibility to communicate on efforts made in reducing environmental impact and has worked on the visualization of its sustainability efforts from the three angles of “climate change,” “natural resources,” and “hazardous substances.”

Elephantech: Company Introduction by CEO 2022 (see 0:38-2:40)

Before: 「Etching unnecessary metal」→ Lot of waste.

Now:「Print the metal you need」→ There's no waste.

EIZO Corp.

EIZO Corp.