Japanese / English

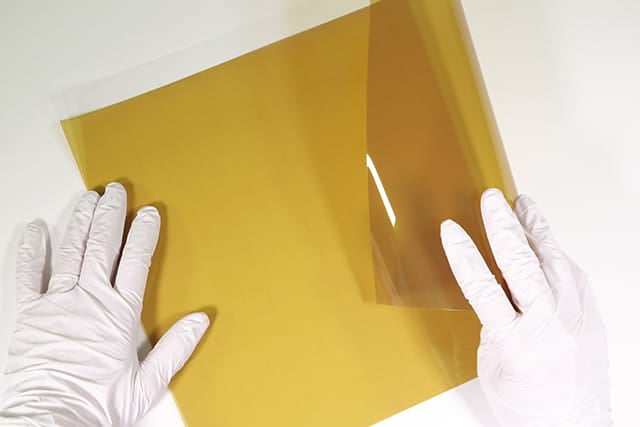

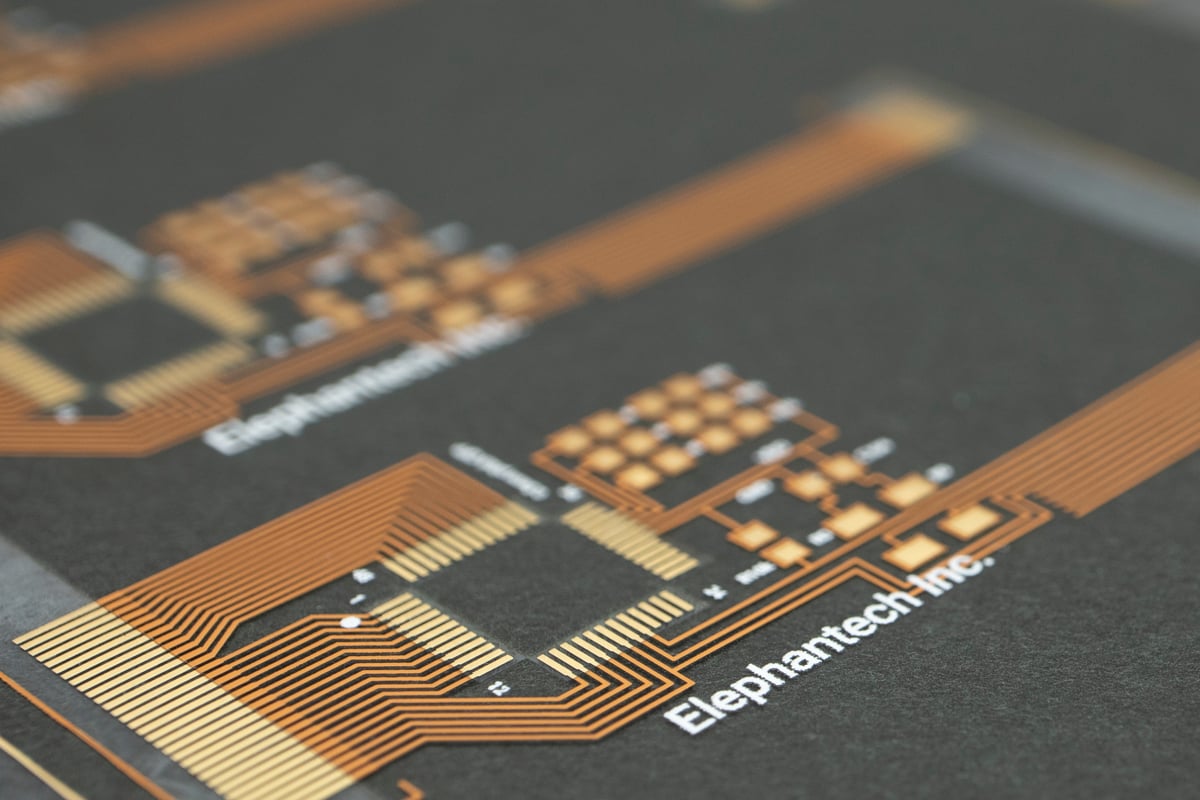

Film

This is the polyimide film used in our substrates. Special surface treatment has been applied to the polyimide film, making it highly adhesive to our silver ink.

Vastly more heat-resistant when compared to our existing heat-resistant PET film, it allows for the use of conventional lead-free solder and solder paste for parts mounting. Also, using a 25µm substrate, its flex resistance and minimum bending radius are improved over that of the existing 50µm substrate PET.

Our existing heat-resistant PET substrate will remain available in two thicknesses: 50µm and 125µm.

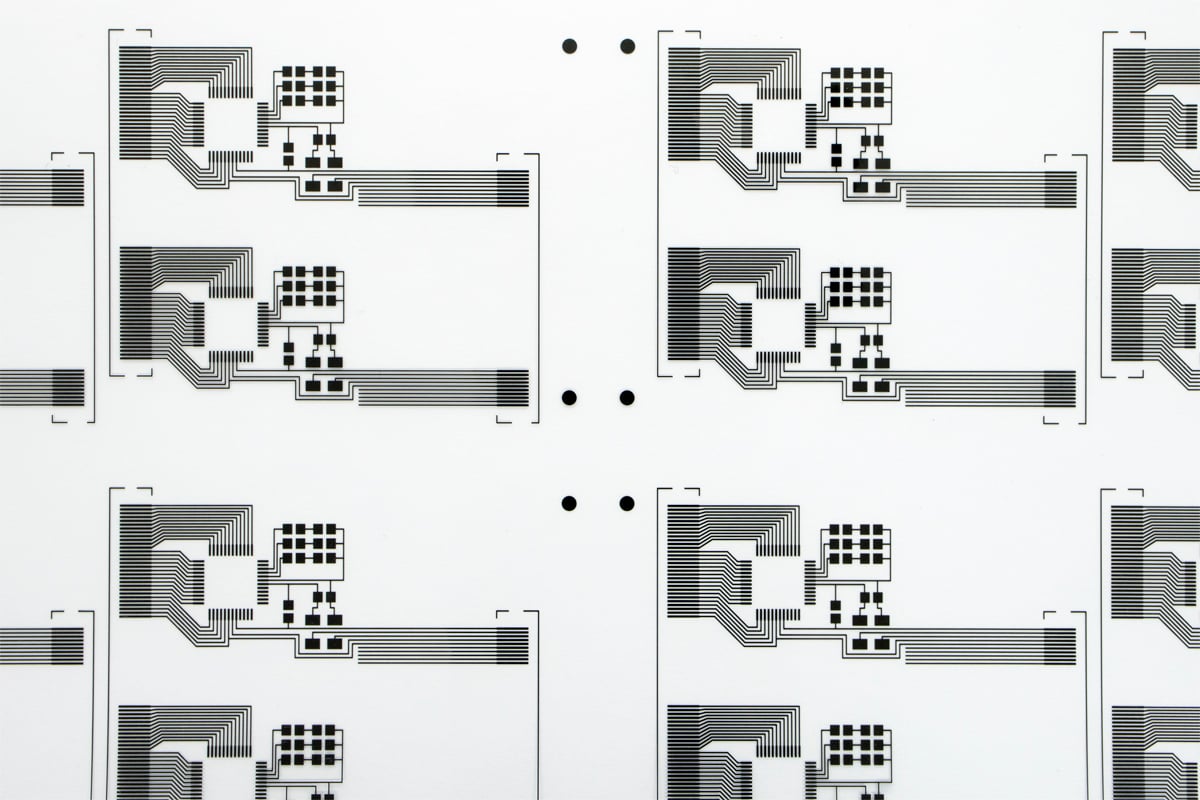

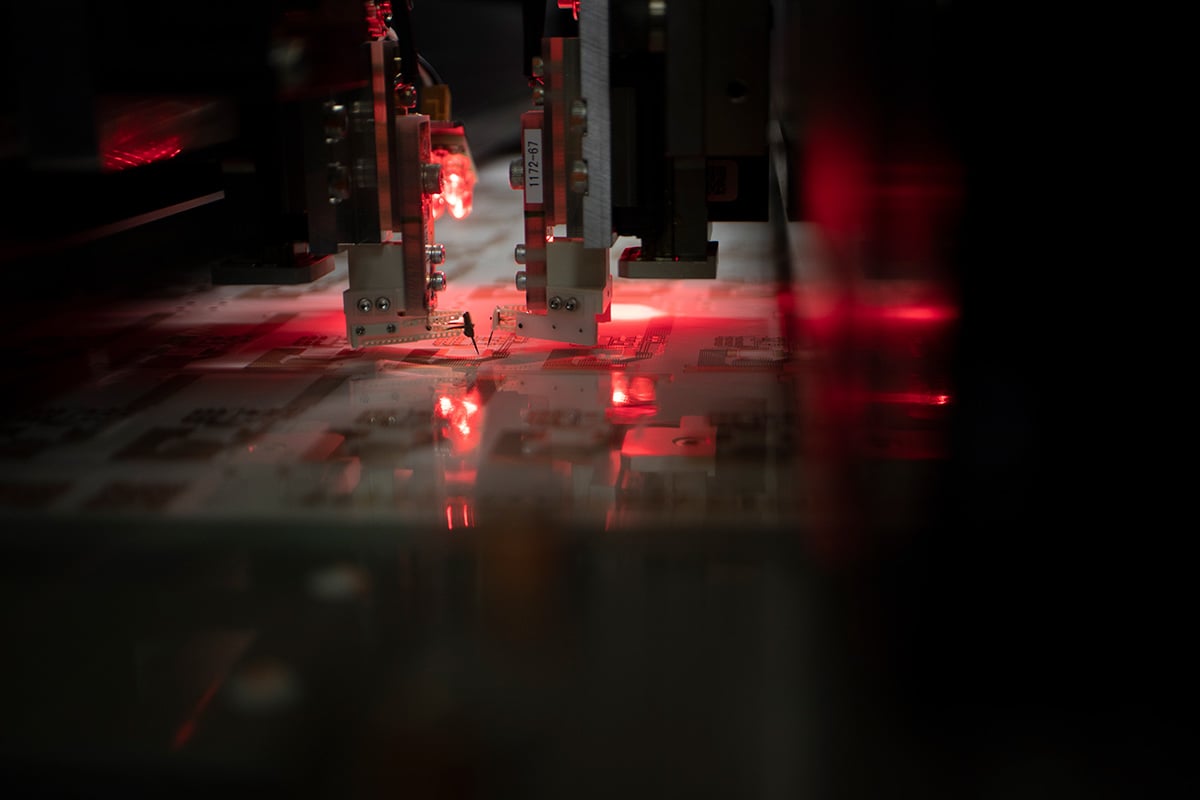

Printing

A process in which silver ink is printed and the silver ink layer is formed.

By adopting an industrial inkjet printer capable of roll-to-roll printing, silver ink is ejected with high precision as an undercoat layer. The minimum line width/line spacing is 200/200μm as standard but can be pushed to 200/150μm as an option.

From small to large lots, the required quantity can be manufactured rapidly as there is no need for plate-making.

Printing with a prototype equipped with an inkjet head similar to the mass production line.

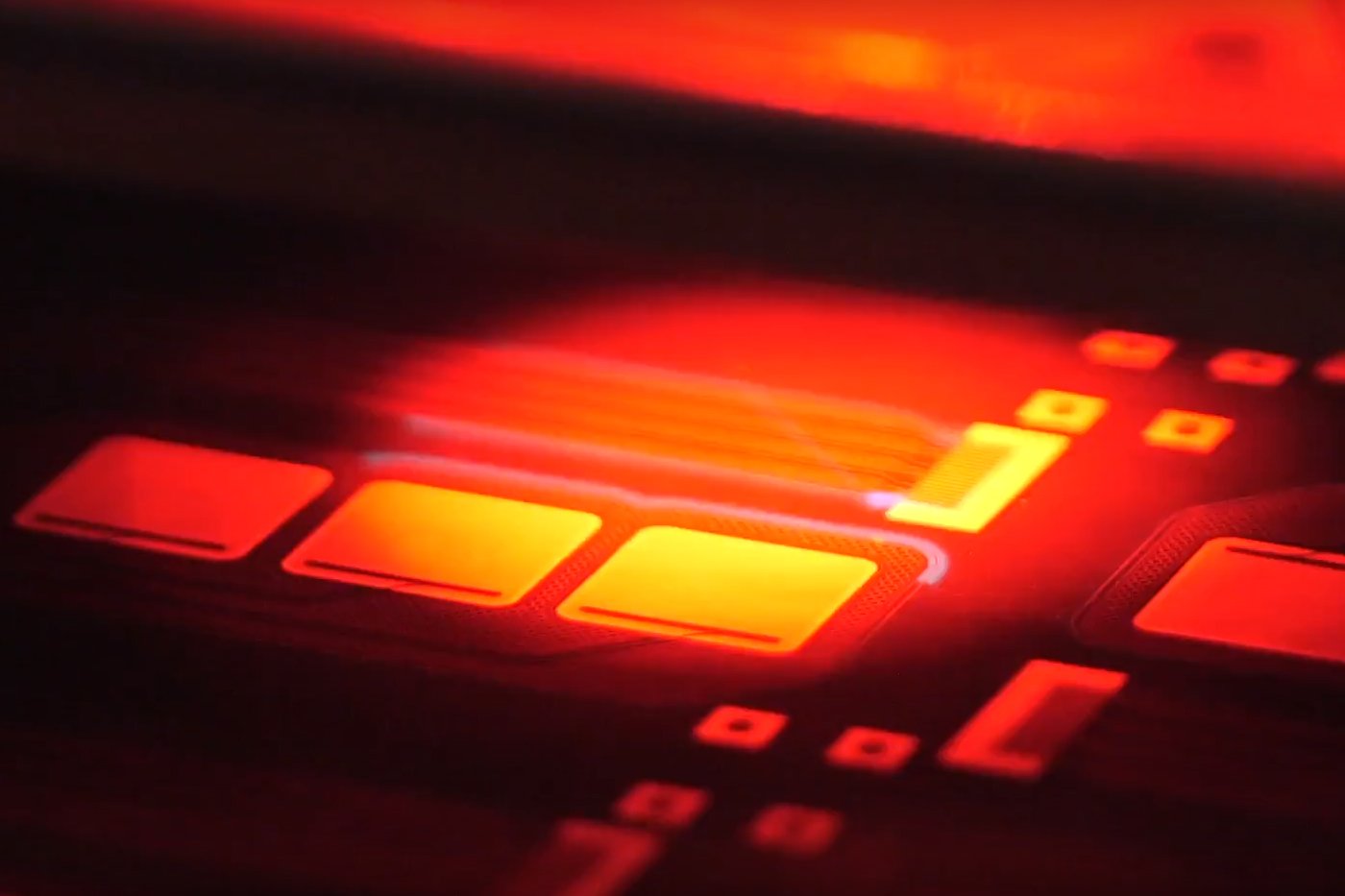

Sintering

A process in which heat treatment is applied to the silver ink layer.

The bond between silver particles in the silver ink is weak when printed, making it unsuitable as a base layer for plating.

This is why we apply our own unique heat treatment to strengthen the bond of the silver particles, forming a strong base layer.

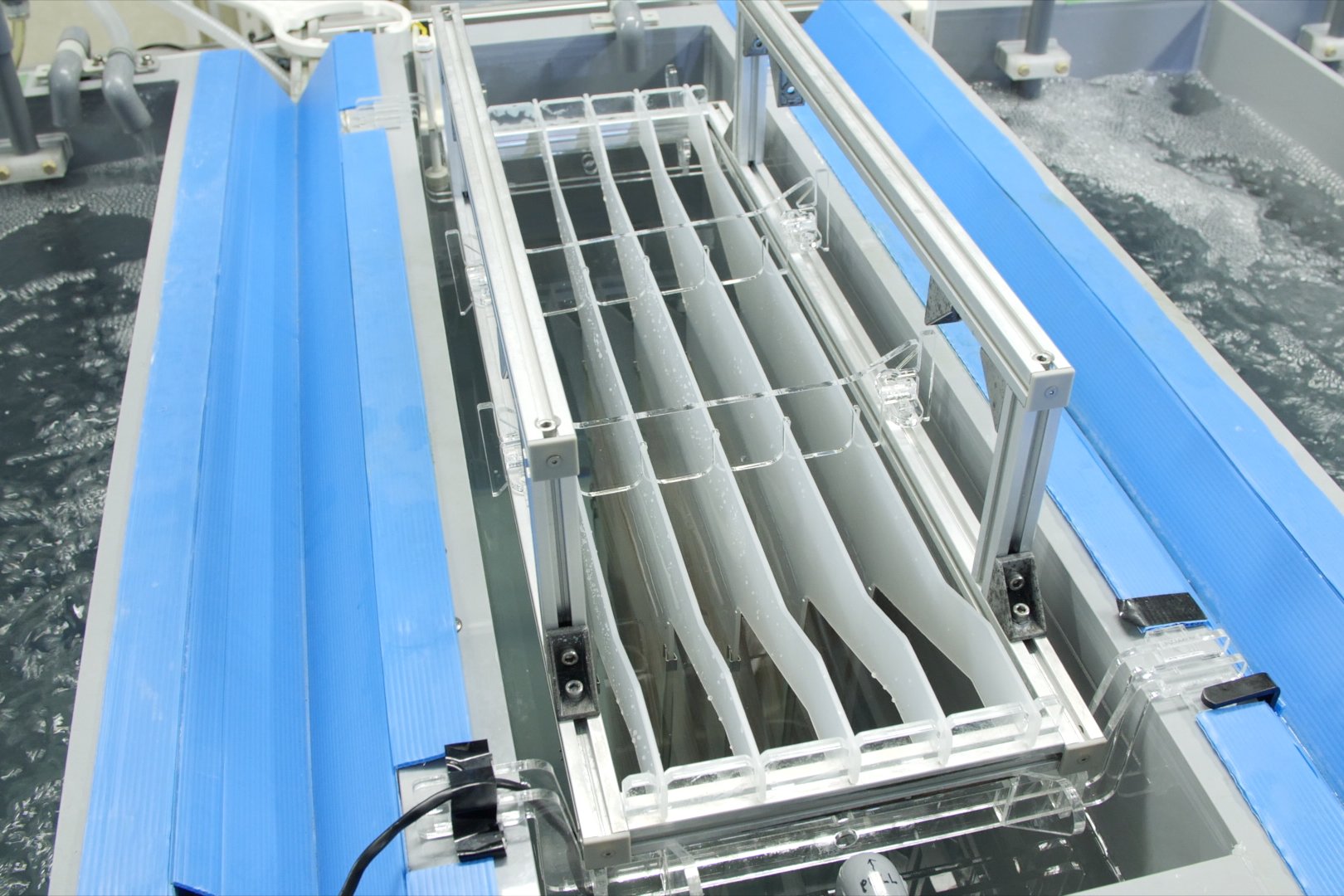

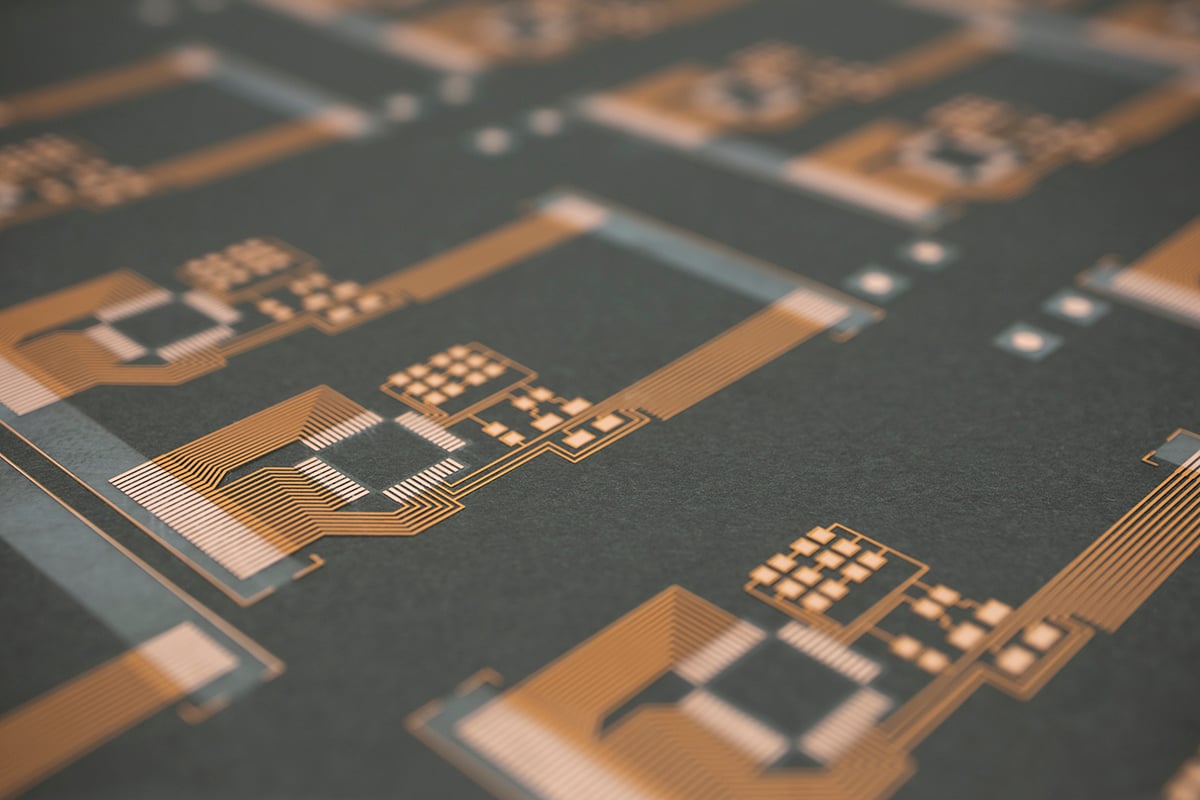

Plating

A process in which a copper layer is formed on top of the silver ink layer by electroless copper plating.

At Elephantech, we have established a technology that forms a copper thick-film layer over a silver ink foundation.

When compared to a simple silver ink layer, adding a copper thick-film layer can lower the electrical resistance by more than 2 digits and also enables conventional soldering.

Soldermask coating

A process in which the soldermask for the flexible PCB is formed.

Soldermasks are used during soldering to prevent the solder from spreading to unnecessary areas and to maintain insulation between circuits.

By using an industrial purpose inkjet printer that doesn't require plate-making and a special soldermasking ink, the soldermask layer formation process can flexibly handle both rapid prototyping and mass production.

Legend

Legends are printed characters that support the mounting procedure and are also known as "silk-screen printing".

At Elephantech, we refer to it as legend printing as we print the characters by inkjet.

Open/short test

We use an equipment called the flying probe to conduct our open/short tests. Two contact pins are moved at high speed to verify that the terminals are connected and that any unintended parts aren't connected. The quality of the product is evaluated by comparing the results with the readings from the circuit board.

Cutting

A process in which a circuit is cut out from a rectangular film substrate in a specified shape.

Using our own high-precision alignment technology and shrinkage correction technology during the cutting process, we are able to provide extremely high cut repeatability.

Inspection

The inspection that follows the cut is our final inspection and we check for defects and scratches to the wiring, presence of foreign matter, misalignment between wiring and cutting, and any misalignment of more than 0.2mm between soldermask and pattern.

Other than this final inspection, there are various inspections all along the manufacturing process such as checking for the presence of spreading or chipping in the printed pattern or whether the plating thickness is as specified.